Double Chamber Vacuum Sealers: Your Ultimate Packaging Solution

Double chamber vacuum sealers are invaluable tools in commercial kitchens, commissaries, and meat and fish processing facilities, providing improved efficiency, dependable quality, and versatile packaging solutions. These machines offer numerous benefits that make them essential for food processing and packaging tasks. The VacMaster® VP400, VP600, and VP800 models each bring unique features and advantages, making them standout choices for anyone looking to take their vacuum packaging to the next level.

Double the Chamber, Double the Benefits

Double chamber vacuum sealers are designed to streamline packaging operations, offering increased productivity and dependable sealing ability. By incorporating VacMaster double chamber vacuum sealers into their operations, businesses involved in food processing, packaging, and other industries requiring top-of-the-line vacuum sealing will find that these powerful machines are game changers. Let’s break down the benefits and features:

1. Increased Efficiency

Simultaneous Sealing & Prepping: The pivoting vacuum chamber allows for sealing one batch of product while the other is being prepared, reducing downtime and increasing the speed of production. This is an invaluable asset for high-volume operations where a continuous workflow is important. By simplifying the sealing process and eliminating any delays, businesses can optimize their packaging operations and count on a smooth production cycle.

Greater Output: With the ability to process large quantities of products continuously, VacMaster double chamber vacuum sealers offer a significant boost in output. This means that a greater number of products can be sealed in a shorter amount of time. By utilizing this feature, businesses can meet high demands and reduce processing times.

2. Consistent Quality

Uniform Vacuum: A consistent vacuum level across all packages is crucial for maintaining product quality and shelf life. A uniform vacuum also helps in preventing spoilage and keeping things fresh for a longer period. Whether you're storing delicate produce, savory meats, or sensitive electronics, a uniform seal will be your best ally in keeping everything in top condition.

Reliable Sealing: Creating consistent and durable seals minimizes the chances of leaks and contamination, which upholds the condition of the packaged items. VacMaster double chamber vacuum sealers use a dual wire seal bar to deliver a robust double bag seal. This ensures that products remain fresh, secure, and protected.

3. Versatility

Wide Range of Products: Whether you are looking to preserve meats or cheeses, seal delicate medical supplies, or protect electronic components from moisture and dust, VacMaster double chamber vacuum sealers offer a versatile solution and a valuable tool for a wide range of industries.

Customizable Settings: The adjustable vacuum and sealing parameters are designed to cater to a wide range of products and packaging materials. This feature provides meticulous control over the sealing process for optimal results for each product type.

4. Cost Savings

Reduced Labor Costs: Increased automation and efficiency require fewer labor needs. This not only cuts costs but also minimizes the potential for human error in the sealing process.

Minimized Waste: Consistent sealing quality reduces product spoilage and packaging material waste. By maintaining a high standard of sealing, companies can avoid the costs associated with wasted products and materials.

5. Extended Product Shelf Life

Improved Preservation: Removing air with proper sealing can significantly extend the shelf life of perishable goods by preventing oxidation, freezer burn, and microbial growth. This preservation is vital for preserving the quality and safety of food products over time.

6. Durability and Longevity

Robust Construction: The VacMaster double chamber machines are built with high-quality materials designed to withstand rigorous use in commercial settings. This level of durability guarantees that the equipment can handle heavy usage without frequent breakdowns.

Low Maintenance: These double chamber machines are designed for easy maintenance and long-term use, reducing downtime and repair costs. Simple maintenance routines help keep the machine running smoothly and orderly.

7. Compliance and Safety

Hygienic Design: Meeting food safety and sanitation standards is crucial in food packaging. VacMaster double chamber machines are made with easy-to-clean materials and are designed to minimize harborage points, reducing the risk of bacterial growth and ensuring compliance with essential food industry standards.

Consistent Performance: Reliable sealing performance not only guarantees adherence to industry packing standards but also ensures that all sealed products meet the required quality and safety regulations regularly. This commitment to quality control instills confidence in both producers and consumers alike.

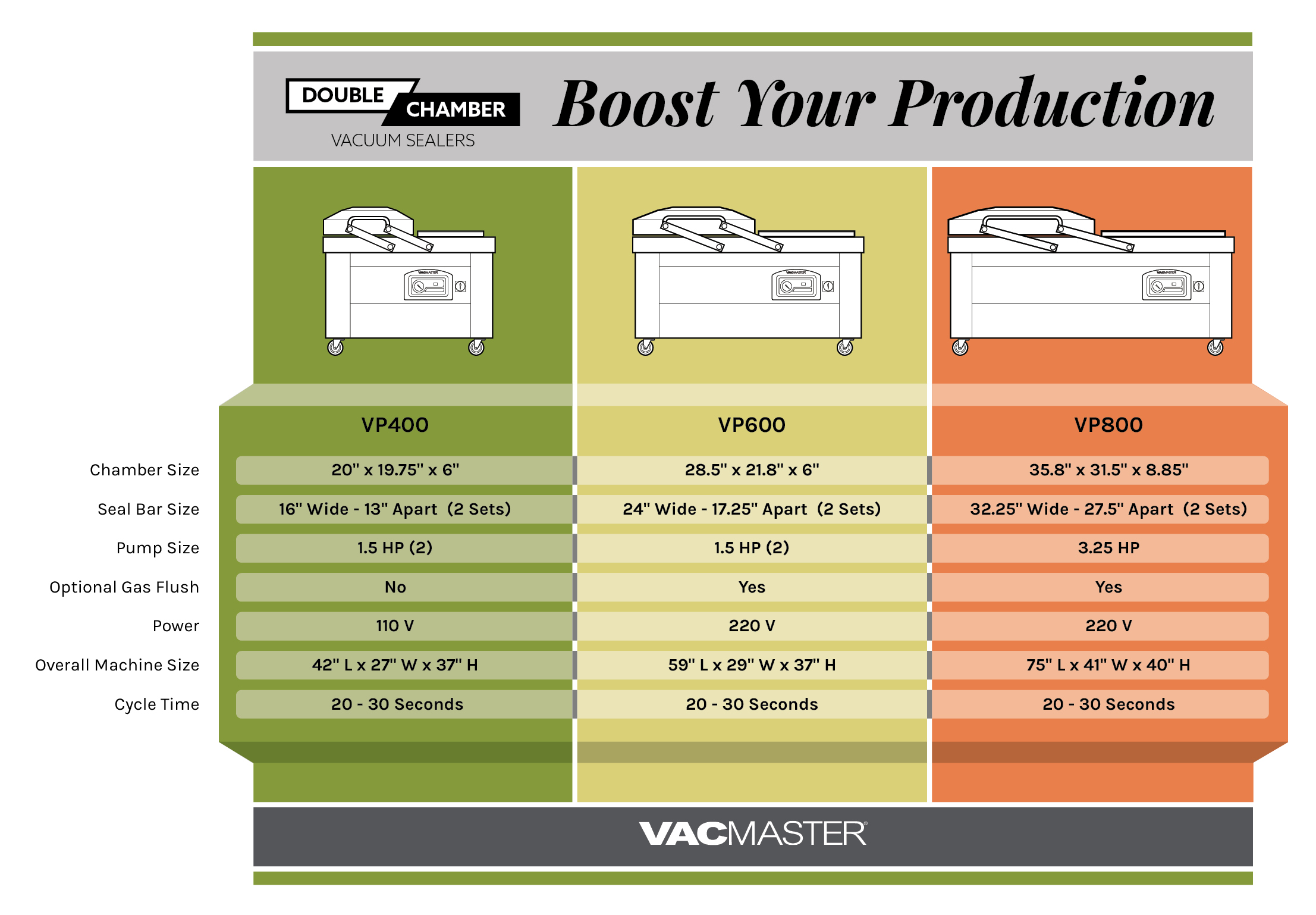

Key Features and Benefits of VacMaster Double Chamber Vacuum Sealer Models

VP400: Compact Powerhouse

The VP400 Double Chamber Vacuum Sealer was designed for those looking to boost their packaging operations without sacrificing floor space.

- Voltage: The only 110 Volt double chamber vacuum sealer on the market, making it accessible for various settings.

- Seal Bars: Four 16" double wire seal bars allow sealing multiple bags at once, enhancing productivity.

- Pump: Commercial-grade 1.5 HP rotary oil pump delivers a superior vacuum in 20-30 seconds.

- Design: Stainless steel body with table height, flat deck design and 4-inch smooth-rolling casters for easy movement. Includes fully skirted access panels to promote easy sanitation.

- Ideal For: Small to medium volume processors, hunting and fishing lodges needing to package large quantities of game quickly.

VP600: Versatile Workhorse

The VacMaster VP600 Commercial Double Chamber Vacuum Sealer provides ample workspace for vacuum packaging a large number of products without occupying large amounts of floor space.

- Seal Bars: Four 24" double wire seal bars offer ample space for various chamber pouches, making it suitable for a wide range of products.

- Pump: Two commercial-grade 1.5 HP rotary oil pumps provide quick and superior vacuum.

- Design: Table height, flat deck design with stainless steel body and smooth-rolling 4-inch casters. Fully skirted access panels to promote easy sanitation.

- Ideal For: Small to medium volume processors, hotels, commissaries, and larger catering providers.

- Gas Flush Ready: This feature allows for the addition of an anaerobic gas mixture, which gives you the ability to package delicate items.

VP800: Ultimate Performer

The VacMaster VP800 Commercial Double Chamber Vacuum Sealer’s double chamber, dual-deck design allows operators to quickly load their product on one side while the other chamber is working.

- Seal Bars: Two 32.25" seal bars with double wire in each vacuum chamber, accommodating a variety of chamber pouches.

- Pump: Powerful commercial-grade 3.25 HP oil pump delivers a quick and superior vacuum.

- Design: Stainless steel body with table height, flat deck design and 4-inch smooth-rolling casters for easy movement. Includes fully skirted access panels to promote easy sanitation. Spring-loaded pivoting chamber lid for smooth back and forth transition, reducing operator fatigue. Designed to withstand years of heavy operation thanks to its reinforced construction and stainless steel base.

- Ideal For: Medium to large volume processors, hotels, commissaries, and large catering providers.

- Gas Flush Ready: This feature allows for the addition of an anaerobic gas mixture, which gives you the ability to package delicate items.

Why Choose Double Chamber Vacuum Sealers?

The VacMaster VP400, VP600, and VP800 double chamber vacuum sealers are a game changer for a broad range of industries. By boosting productivity, delivering reliable results, and offering versatile packaging solutions, these powerful machines revolutionize meal prep, uphold food safety standards, and reduce unnecessary waste. Whether you're a small-scale processor, a hunting lodge in need of game packaging solutions, or a hospitality provider aiming to streamline operations, there's a VacMaster model tailored to meet your specific needs. Equipped with features like multiple seal bars, high-performance pumps, and optional gas flush capabilities, these vacuum sealers are designed to transform you into a vacuum packaging pro.

Integrating a double chamber vacuum sealer into your culinary or business setup translates to reduced downtime and increased productivity. By maintaining a dependable vacuum level and strong seals, these machines help reduce labor expenses and minimize waste, leading to significant cost savings. VacMaster double chamber vacuum sealers improve the quality of your goods and extend their shelf life, all while meeting packaging standards.

The VacMaster VP400, VP600, and VP800 models boast a sturdy build, low maintenance requirements, and reliable performance. These vacuum sealers will undoubtedly boost your packaging operations to new heights. Explore the complete range of VacMaster products to discover your perfect fit and unlock the full potential of your packaging needs.

Shop VacMaster Double Chamber Vacuum Sealing Machines

On sale now through August!